Voigt-Abernathy is your specialist for EagleBurgmann Products in

Alabama, Arkansas, Florida, Mississippi and Tennessee.

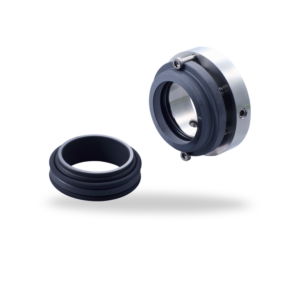

Single and Double Mechanical Seals

A mechanical seal for pumps is a component designed to prevent fluid leakage where the pump shaft exits the casing. It consists of two main parts: a rotating component attached to the shaft and a stationary component fixed within the pump housing. These parts have smooth sealing faces that press together to form a tight barrier against leakage during pump operation. Different types of mechanical seals, made from materials like carbon and ceramic, are used based on pump requirements and fluid compatibility. Proper installation and maintenance are crucial to ensure effective sealing and prolong the lifespan of the mechanical seal.

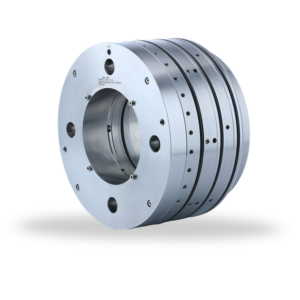

Engineered and Specialty Seals

Engineered seals for pumps are customized sealing systems designed to meet specific pump applications and operating conditions. They incorporate advanced features and materials tailored for demanding environments, such as high temperatures, pressures, or corrosive fluids. These seals optimize sealing performance, minimize leakage, and extend pump reliability by addressing unique operational challenges. Suppliers of engineered seals offer application expertise and support to assist in seal selection, installation, and maintenance for optimal pump performance and longevity.

Gas Compressor Seals

A gas compressor seal refers to a sealing system used in gas compressors to prevent leakage of gas along the compressor shaft where it exits the casing. Gas compressors are used to increase the pressure of various gases for transportation, processing, or storage purposes. The seals used in gas compressors play a crucial role in maintaining efficiency, reliability, and safety by containing the pressurized gas within the compressor system.

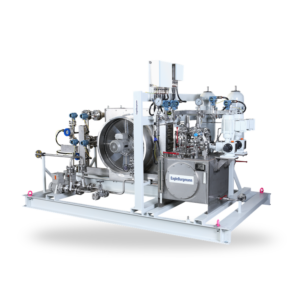

Seal Supply Systems

A seal supply system in mechanical pumps delivers a specific fluid to the mechanical seal, providing lubrication, cooling, and a barrier between sealing faces to prevent fluid leakage. This system also controls fluid pressure to ensure optimal seal performance and incorporates filters for maintaining fluid cleanliness. Monitoring devices are often integrated into seal supply systems to track fluid parameters and enable proactive maintenance. A well-designed seal supply system is essential for maximizing the efficiency, reliability, and lifespan of mechanical seals in pump applications by minimizing leakage and reducing maintenance requirements.

Rotech Boosters

The RoTechBooster features an EBNM high-efficiency magnetic coupling, eliminating the requirement for an extra mechanical seal. This magnetic coupling not only eliminates potential additional system leak paths and emissions but also enhances safety for personnel and enables virtually wear-free operation. The high-efficiency design efficiently transfers torque, resulting in higher pressure ratings and lower operating costs. With this coupling design, maximum RoTechBooster availability is ensured, maintaining abundant seal gas flow across all operating conditions.

To learn more about their products, please contact your local Voigt-Abernathy Sales Engineer or give us a call at (205) 655-0434.

Follow Us!